English

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски

Harmony Reducer CSF-32-30-2UH for Closed Slot Shaving Cutter

Harmony Reducer CSF-32-30-2UH for Closed Slot Shaving Cutter Harmonic Assembly Machine CSF-20-100-2UH-SP

Harmonic Assembly Machine CSF-20-100-2UH-SP Harmony Inertia Drum Gear Harmonic Unit CSF-20-120-2UH

Harmony Inertia Drum Gear Harmonic Unit CSF-20-120-2UH Harmonyx Flex Pulley Harmonic Module CSF-25-30-2UH

Harmonyx Flex Pulley Harmonic Module CSF-25-30-2UH Harmonic Reducer CSF-25-50-2UH

Harmonic Reducer CSF-25-50-2UH Hammerner Kohler Gear Displacement Harmonic Reducer CSF-25-80-2UH

Hammerner Kohler Gear Displacement Harmonic Reducer CSF-25-80-2UH- All new products

Harmonic Drive servo gear unit FHA-25C-160-E250-C

The Harmonic Drive flexible gear contact harmonic FHA-25C-160-E250-CK can generate a flexible gear with radial elastic deformation and external teeth, and a wave generator which is installed inside the flexible gear, is oval in shape, and has a flexible rolling bearing on the outer ring.

Product Description

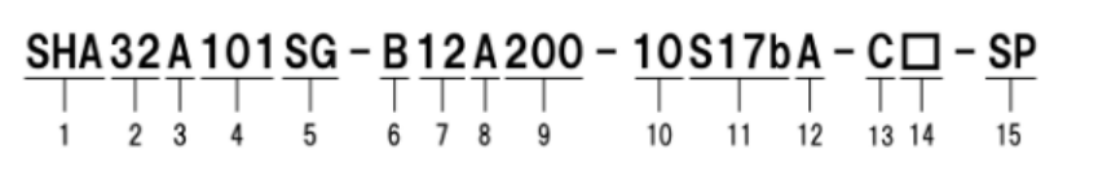

SHA series

Abstract

The following matters should be noted:

(1) Adopt multi-contact zone transmission with splitting and confluence, and adopt unloading structures, such as multi-disc, roller cone flat disc and planetary continuously variable transmission;

(2) Increase the distance between the contact area of the friction pair and the pressure device and the rotation axis as much as possible;

(3) For multi-contact zone transmission, adopt the floating load-sharing structure of the Harmonic Drive flexible gear contact harmonic FHA-25C-160-E250-CK, and strictly control the dimensional deviation and rotation accuracy of a set of rolling elements;

(4) Increase the stiffness of the shafting, limit the length-to-diameter ratio of the shaft extension, and make the transmission and the connected machine be connected in a straight line as much as possible;

(5) When the starting torque is large in use, the starting and braking are frequent, the load changes greatly or there is an impact, electromagnetic clutches, safety clutches or flywheels and other devices should be installed between the transmission and the connected machine;

(6) Adopt an automatic pressure device and reasonably arrange its position and quantity;

(7) Use materials with high elastic modulus and hardness to manufacture the rolling elements. The accuracy of the rolling elements should be above grade G5, and they should be selected and grouped;

(8) Select the appropriate traction oil and lubrication method (oil volume, oil change time and unobstructed flow of the oil circuit, etc.) through tests or experience;

(9) Check the thermal carrying capacity and consider the adoption of a cooling device.

In order to improve the transmission efficiency of the transmission and reduce sliding and wear, attention should be paid to:

(1) Strive to make the equivalent cones of the friction pair at any speed regulation position of the Harmonic Drive flexible gear contact harmonic FHA-25C-160-E250-CK be able to have a common vertex, or the two cone vertices are on the same side of the contact area and are as close as possible to improve the parallelism accuracy of the two parallel axes;

(2) Under the condition of meeting the strength requirements, reduce the contact width or adopt a point contact structure

Specialties

HarmonicDrive ® Integrated AC servo actuator with specially designed flat AC servo motor

Hollow and flat structure

Absolute value encoder

SHA-SG: Compact shape with extra length

SHA-CG: For turntable use, improve the accuracy of output shaft surface vibration

1. Model name: AC servo actuator SHA series

2. Model:

SG type=20, 25, 32, 40, 45, 58, 65

HP type=25,32

CG type=20,25,32,40

3. Version symbols

4. HarmonicDrive ® Reduction ratio:

SG type=51,81101121161

HP type=11

CG type=50,80100120160

5. Type of reducer:

SG type=SHG series

HP type=HPF series

CG type=CSG series

6. Motor version symbol:

A=Models 58, 65

B=Models 25, 32, 40

C=Model 20

D=Model 45

7. Motor size:

● 08=Model 20

09=Model 25

12=Model 32

15=Model 40

16=Model 45

21=Models 58, 65

8. Brake:

● A=No brake

● B=With brake

9. Motor power supply voltage:

100=AC100V

200=AC200V

10. Encoder format:

10=symbol A format, transmission speed: 2.5Mbps, 1:1 connection

11. Encoder type and resolution:

S17b=17bit absolute encoder 131072 pulses/rotation

12. Encoder phase angle:

The phase difference A between the U-phase induced voltage of the motor and the absolute origin is 0 degrees

13 connector specifications:

● C=With standard connectors

● N=No connector

D=With special connectors

14. Optional symbols:

L=Near Origin&End Limit Sensor

Y=Cable side exit

● V=With bracket (CG type only)

● S=Output shaft 1 rotation absolute value specification (CG type only)

● No entry=standard product

SP=non-standard product