English

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски

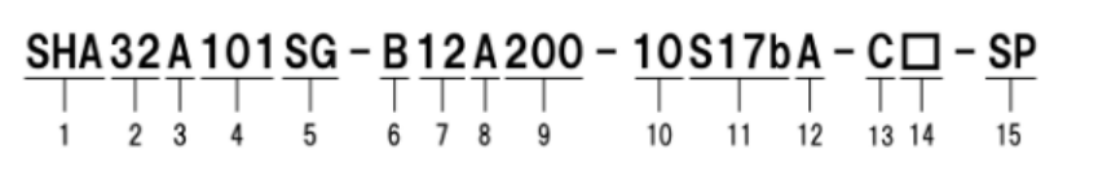

Harmonic Drive servo component FHA-11C-30-E200-C

Harmonic Drive servo component FHA-11C-30-E200-C is an engine used in servo systems to control the operation of mechanical components. It serves as an auxiliary motor with an indirect variable speed mechanism. Servo motors enable precise control over speed and positional accuracy, converting voltage signals into torque and rotational speed to drive controlled objects.

Servo motors are classified into two main types: DC and AC servo motors. Their key characteristic is that they do not rotate on their own when no voltage signal is applied, and their rotational speed decreases uniformly with increasing torque load.

Product Description

SHA series

Abstract

The Harmonic Drive servo component FHA-11C-30-E200-C is a device used in servo systems to control the operation of mechanical components. It serves as an auxiliary motor with an indirect variable speed mechanism. Servo motors enable precise control over speed and positional accuracy, converting voltage signals into torque and rotational speed to drive controlled objects.

In typical control systems, the step response is a key indicator used to evaluate the speed and accuracy of the system's response. It includes several parameters:

- Overshoot : Measures the approximate standard of system stability.

- Rise Time : Time taken for the maximum overshoot to occur.

- Settling Time : Time required for the response to settle within a specified percentage (typically ±2% or ±5%) of the steady-state value.

- Half-peak Time : Time taken for the response to rise from 10% to 90% of the steady-state value.

- Steady-state Error : Error in the output response when it reaches a steady state.

Frequency response analysis evaluates how well the system tracks a sinusoidal input signal. Parameters include:

- Resonance Peak of Frequency Response : Maximum peak amplitude of the output response.

- Resonance Frequency : Frequency at which the resonance peak occurs.

- Bandwidth : Frequency at which the output frequency response decreases to half of its maximum value.

Pneumatic servo mechanisms, using compressed gases as working fluids, are suitable for high-power control systems. However, due to the compressibility of gases, they are not ideal for high-speed responses. Nevertheless, gas leaks are manageable, and the low cost of gas makes them widely used in general factory applications.

In summary, servo mechanisms are designed to track and control systems accurately. Performance evaluation considers both the system's ability to respond rapidly to changes in input (step response) and its ability to track sinusoidal input variations (frequency response).

Specialties

HarmonicDrive ® Integrated AC servo actuator with specially designed flat AC servo motor

Hollow and flat structure

Absolute value encoder

SHA-SG: Compact shape with extra length

SHA-CG: For turntable use, improve the accuracy of output shaft surface vibration

1. Model name: AC servo actuator SHA series

2. Model:

SG type=20, 25, 32, 40, 45, 58, 65

HP type=25,32

CG type=20,25,32,40

3. Version symbols

4. HarmonicDrive ® Reduction ratio:

SG type=51,81101121161

HP type=11

CG type=50,80100120160

5. Type of reducer:

SG type=SHG series

HP type=HPF series

CG type=CSG series

6. Motor version symbol:

A=Models 58, 65

B=Models 25, 32, 40

C=Model 20

D=Model 45

7. Motor size:

● 08=Model 20

09=Model 25

12=Model 32

15=Model 40

16=Model 45

21=Models 58, 65

8. Brake:

● A=No brake

● B=With brake

9. Motor power supply voltage:

100=AC100V

200=AC200V

10. Encoder format:

10=symbol A format, transmission speed: 2.5Mbps, 1:1 connection

11. Encoder type and resolution:

S17b=17bit absolute encoder 131072 pulses/rotation

12. Encoder phase angle:

The phase difference A between the U-phase induced voltage of the motor and the absolute origin is 0 degrees

13 connector specifications:

● C=With standard connectors

● N=No connector

D=With special connectors

14. Optional symbols:

L=Near Origin&End Limit Sensor

Y=Cable side exit

● V=With bracket (CG type only)

● S=Output shaft 1 rotation absolute value specification (CG type only)

● No entry=standard product

SP=non-standard product