English

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски

Harmony Reducer CSF-32-30-2UH for Closed Slot Shaving Cutter

Harmony Reducer CSF-32-30-2UH for Closed Slot Shaving Cutter Harmonic Assembly Machine CSF-20-100-2UH-SP

Harmonic Assembly Machine CSF-20-100-2UH-SP Harmony Inertia Drum Gear Harmonic Unit CSF-20-120-2UH

Harmony Inertia Drum Gear Harmonic Unit CSF-20-120-2UH Harmonyx Flex Pulley Harmonic Module CSF-25-30-2UH

Harmonyx Flex Pulley Harmonic Module CSF-25-30-2UH Harmonic Reducer CSF-25-50-2UH

Harmonic Reducer CSF-25-50-2UH Hammerner Kohler Gear Displacement Harmonic Reducer CSF-25-80-2UH

Hammerner Kohler Gear Displacement Harmonic Reducer CSF-25-80-2UH- All new products

Precision ground harmonic drive gear reducer CSF-14-30-2UH

The imported precision ground harmonic drive gear reducer CSF-14-30-2UH mainly consists of three basic components: the wave generator, flexible gear, and rigid gear. The harmonic drive reducer is a type of gear transmission where the wave generator induces controlled elastic deformation in the flexible gear, which then meshes with the rigid gear to transmit motion and power.

Product Description

gearbox

Abstract

When using an end mill to mill the outer circle, high cutting efficiency can be achieved, and reliable chip breaking is also an important issue in the automation of the machining process. When milling, the milling cutter and the workpiece are arranged perpendicular to each other, using the imported precision ground harmonic drive gear reducer CSF-14-30-2UH. By offsetting the position between the center of the milling cutter and the axis of the workpiece, three types of forming motions—workpiece rotation speed, axial feed motion, and cutting depth—can be adjusted to mill various shapes on the workpiece.

Ultra-precision grinding, also known as super-finishing, is a method of surface finishing using a grinding bar. During operation, the workpiece rotates, and the grinding bar applies low-frequency vibrations of 8 to 35Hz and a small pressure with the imported precision ground harmonic drive gear reducer CSF-14-30-2UH to achieve a complex intersecting pattern of abrasion marks, resulting in a machining surface with extremely low roughness.

Longitudinal turning of the outer circle on a longitudinal automatic machine completes the main motion by rotating the bar stock, while the axial feed motion is controlled by a cam. This method is used for machining small precision parts and is an efficient and simple automated method for machining outer circle surfaces, widely used in mass production.

Internal bore machining involves cutting within the workpiece, where chip removal and heat dissipation conditions are poor, and the size is constrained by the diameter, making it more challenging than outer circle machining. Due to varying requirements in hole size and quality, there are several methods for hole machining, as listed in Table 1-2. Below are explanations of these methods.

Drilling is generally used to machine holes ranging from 0.2 to 80mm in diameter on solid materials. There are various drilling methods available; on conventional drilling machines or radial drilling machines, the main motion and feed motion are typically completed by the machine. When drilling on a lathe, the main motion is completed by the workpiece, and the feed motion can be completed by the machine or the workpiece (as in longitudinal automatic machines). On combination machine tools, the tool completes the main motion, while the feed motion is completed by the workpiece.

Specialties

It is a combination type equipped with high rigidity bearings (cross roller bearings) that are suitable for servo motors of various companies and have a one click installation feature.

High torque

Long lifespan (increased rated lifespan)

No back gap

CSF series ratio: increases torque capacity by 30%

43% increase in lifespan (10000 hours)

※ Motor matching can be confirmed through selection tools

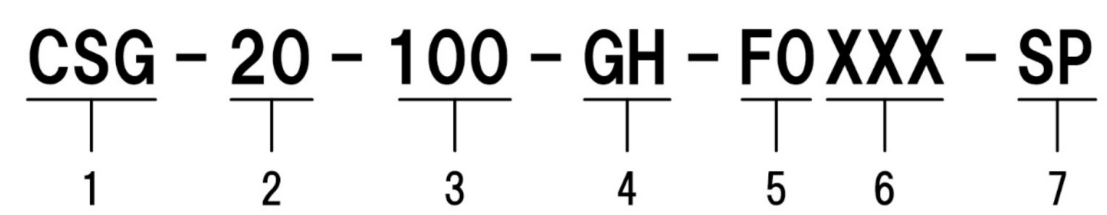

1. Model name: CSG series

2. Models: 14, 20, 32, 45, 65

3. Reduction ratio: 50, 80, 100, 120, 160

4. Type: GH=gearbox type

5. Output shaft shape:

F0=flange output

J2=straight axis (keyless)

J6=Straight axis (with key and center screw hole)

6. The shape of the motor flange and input shaft coupling shall comply with (depending on the installation of the motor)

7. Non standard products:

● Unsigned=standard product

SP=non-standard product