English

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски

Harmonic Gearbox CSF-32-100-2UH

Harmonic Gearbox CSF-32-100-2UH Harmonic Unit of Harmony Tester CSF-32-80-2UH

Harmonic Unit of Harmony Tester CSF-32-80-2UH Harmony Reducer CSF-32-30-2UH for Closed Slot Shaving Cutter

Harmony Reducer CSF-32-30-2UH for Closed Slot Shaving Cutter Harmonic Assembly Machine CSF-20-100-2UH-SP

Harmonic Assembly Machine CSF-20-100-2UH-SP Harmony Inertia Drum Gear Harmonic Unit CSF-20-120-2UH

Harmony Inertia Drum Gear Harmonic Unit CSF-20-120-2UH Harmonyx Flex Pulley Harmonic Module CSF-25-30-2UH

Harmonyx Flex Pulley Harmonic Module CSF-25-30-2UH- All new products

Harmonic Drive Etching Machining Harmonic Gear CSF-17-100-2UH

The controller's control over a certain transmission results in an adjustable output speed range of 1 to 540 rpm.

Product Description

gearbox

Abstract

The controller's control over a certain transmission results in an adjustable output speed range of 1 to 540 rpm. The load variation ranges from 0 to 20 Nm. Within the entire speed range, the speed fluctuation is within ±2 rpm. The Harmonic Drive Flexible Transmission Harmonic Gear CSF-17-100-2UH requires high speed control accuracy, achieving up to 1% precision. It should be noted that speed control operates under the condition that the load torque does not exceed the maximum output torque provided by the prime mover. It becomes ineffective during overload conditions. The selection of control accuracy should meet user requirements without being excessively high to avoid affecting the lifespan of the executing motor.

The rigid fixed-axis infinitely variable transmission consists of rigid transmission components. When the Harmonic Drive Flexible Transmission Harmonic Gear CSF-17-100-2UH is not adjusting speed, the rotating axis positions of each transmission component remain fixed, but they vary during speed adjustment. It features a simple structure and diverse forms. It is divided into two categories: with and without intermediate rollers. The former has a larger speed adjustment ratio (Rb = 1 to 21), while the latter has Rb = 6. To improve the power-to-volume ratio, a multi-intermediate transmission method is commonly used. For variable speed devices that require both acceleration and deceleration, two sets of pressurization devices are generally used. The contact area of transmission components can be designed as either initial point or line contact structures. The former has slightly lower load capacity but less relative sliding, compensating for deformation due to force and errors in processing and assembly. The latter has higher load capacity but requires higher manufacturing and assembly precision.

During speed adjustment, due to the significant axial displacement of the speed transmission components, only columnar helical springs and large-angle cylindrical end cam pressurization devices can be used.

Specialties

It is a combination type equipped with high rigidity bearings (cross roller bearings) that are suitable for servo motors of various companies and have a one click installation feature.

High torque

Long lifespan (increased rated lifespan)

No back gap

CSF series ratio: increases torque capacity by 30%

43% increase in lifespan (10000 hours)

※ Motor matching can be confirmed through selection tools

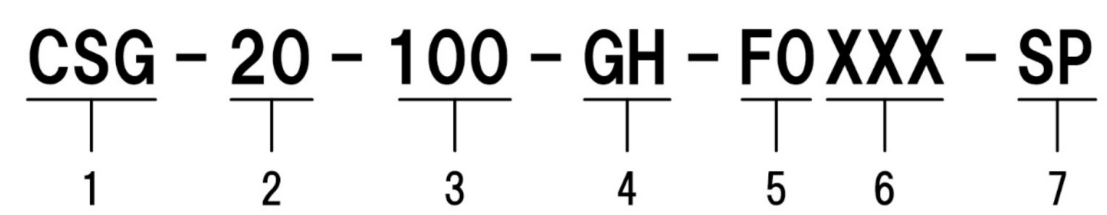

1. Model name: CSG series

2. Models: 14, 20, 32, 45, 65

3. Reduction ratio: 50, 80, 100, 120, 160

4. Type: GH=gearbox type

5. Output shaft shape:

F0=flange output

J2=straight axis (keyless)

J6=Straight axis (with key and center screw hole)

6. The shape of the motor flange and input shaft coupling shall comply with (depending on the installation of the motor)

7. Non standard products:

● Unsigned=standard product

SP=non-standard product