What is a harmonic actuator?

What is a harmonic actuator

harmonic actuator

In the rapid development of modern industry and robotics, harmonic actuators have gradually become one of the key components. Its unique design and performance make it play an important role in the field of precision control and high efficiency. So, what is a harmonic actuator?

Basic principle of harmonic actuator

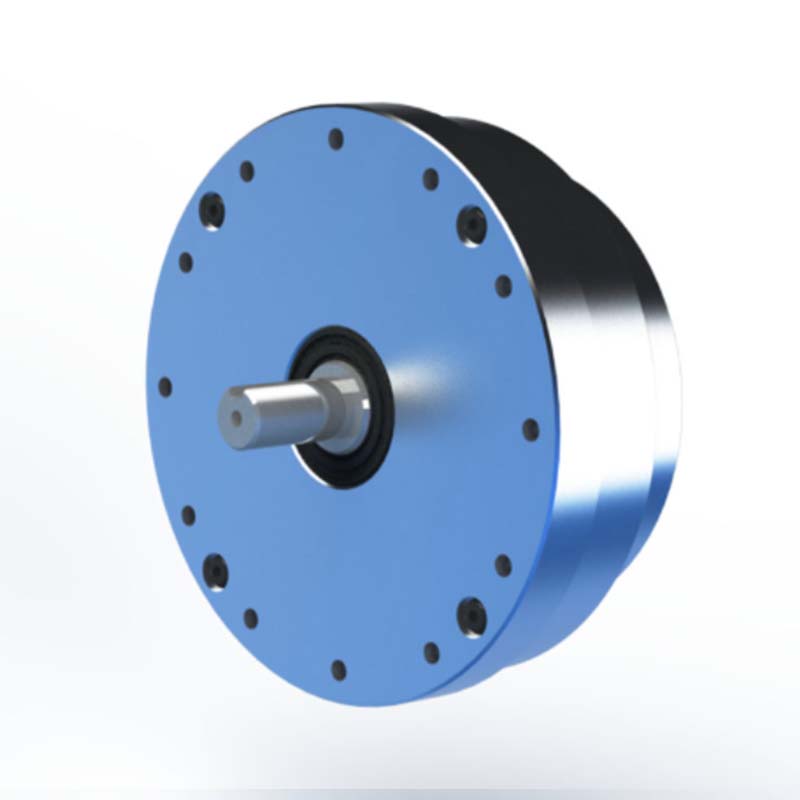

Harmonic actuator, also known as harmonic reducer, is a mechanical device that achieves high precision and high reduction ratio through flexible gear transmission. It consists of three main parts: wave generator, flexible wheel and rigid wheel. The wave generator is usually an elliptical cam installed in the flexible wheel, which produces periodic elastic deformation through rotation. The flexible wheel meshes with the rigid wheel to achieve torque transmission and deceleration effect.

High precision and high reduction ratio

The biggest advantage of harmonic actuators lies in their excellent precision and high reduction ratio. Due to the elastic deformation of the flexible wheel, it can achieve multi-tooth contact with the rigid wheel, which greatly reduces the transmission error and backlash. Common harmonic actuators can achieve a reduction ratio of 100:1 or even higher, and the transmission efficiency can reach more than 90%. This high precision and high efficiency make it extremely advantageous in applications that require precise positioning and control.

Wide range of applications

The application range of harmonic drives is very wide, covering a variety of fields from industrial robots to aerospace. In industrial robots, harmonic drives are used to drive the joints of the robotic arm, providing high-precision position control and stable operating performance. In medical equipment, harmonic drives are used in surgical robots to help achieve precise operations in minimally invasive surgery. In addition, harmonic drives also have important applications in aerospace, semiconductor manufacturing, optical equipment, and electric vehicles.

Environmental protection and economic benefits

Harmonic drives not only perform well in technical performance, but also have significant environmental and economic benefits. Due to their high efficiency and low hysteresis, harmonic drives can reduce energy consumption and improve the overall operating efficiency of equipment. At the same time, their compact design and long life reduce maintenance costs and downtime, and improve the economy of equipment.

In the future, with the continuous advancement of science and technology and the increase in application needs, the technology of harmonic drives is also developing. Future harmonic drives will pay more attention to miniaturization, lightweight and high load-bearing capacity to adapt to more complex and diverse application scenarios. In addition, the development of intelligence and digitalization will also promote the deep integration of harmonic drives and control systems to achieve a higher level of automation and intelligence.

In summary, as a high-precision and high-efficiency mechanical transmission device, harmonic drives play an irreplaceable role in modern industry and robotics. With the continuous advancement of technology and the expansion of application fields, harmonic drives will surely play a more important role in the future development of intelligent manufacturing and automation.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски

A Giant Eye Exploring the Origins of the Universe: The Optical Marvel of the Subaru Telescope

As an international collaborative project led by the National Astronomical Observatory of Japan, its name comes from the Pleiades (M45), symbolizing the collective wisdom and global collaboration of the Japanese astronomical community.

Read MoreSpace Industry: HarmonicDrive® and Humanity's First Round Trip to the Asteroid Belt

The space industry, as a cutting-edge field for human exploration of the universe and development of space resources, is developing at an unprecedented pace.

Read MoreHarmonic Drives: The "Space Joints" of NASA's Perseverance Rover's Robotic Arm

In February 2021, NASA's Perseverance rover successfully landed on the Martian surface, marking a new era in human exploration of Mars. One of the most striking technological highlights of this 1025-kilogram "Mars scientist" is its robotic arm system—five Harmonic Drive® units serve as the core transmission components, ensuring the precise operation of scientific instruments in the extreme Martian environment.

Read More